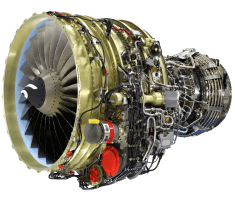

For more than four decades, CFM International has invested in technologies to make our engines cleaner, quieter, and more efficient. Ever more sustainable products: with each new engine model, from the ubiquitous CFM56 family, through to the very latest generation of LEAP engines, CFM has continuously introduced technologies that have significantly improved fuel efficiency, lowered CO2 and NOx emissions, and reduced noise. Although all CFM products comply with the highest standards set by ICAO*, CFM is committed to do even more.

On June 14, 2021, GE and Safran Aircraft Engines officially launched the CFM RISE (Revolutionary Innovation for Sustainable Engines) Program as a manifestation of their deep commitment for achieving aggressive goals for a sustainable future, including reducing fuel consumption and CO2 emissions by more than 20 percent.

Building on four decades of investments that have made our engines cleaner, quieter, and more efficient,

the RISE Program accelerates the development of uncompromising new propulsion technologies that will pave the way for the next generation of aircraft and an ever more sustainable future.

The program embodies CFM’s mission to push the limits of innovation to develop, demonstrate, and bring to market breakthrough technologies that will advance the industry and protect the planet.

*RISE is a registered trademark of CFM International

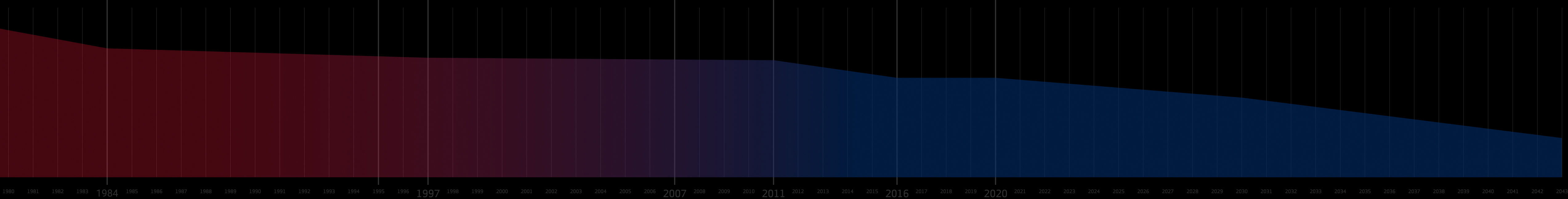

CFM56-3 high-bypass turbofan reduced fuel burn and CO2 emissions by 24% vs. older low-bypass engines

LEARN MORE

CFM56-5B/-7B Tech Insertion introduced new combustor technology to reduce NOx by 25%

LEARN MORE

CFM56-5B PIP and CFM56-7BE reduced fuel burn and CO2 emissions by an additional 2% vs. base engines

LEARN MORE

LEAP engines introduced an impressive package of innovative technologies, setting a new standard, providing a 20% reduction in fuel consumption and CO2 emissions. CFM products brought total improvements of 40% since 1980s.

LEARN MORE

Advanced, disruptive technology could bring up to a 20% reduction in fuel burn and CO2 vs. today’s LEAP engine family. Technology is 100% compatible with sustainable fuels.

We believe there is a clear path to get us where we need to be; our industry has been constantly improving fuel efficiency, noise, and emissions as better and better technology has been developed.

GAËL MÉHEUST, CEO/PRESIDENT, CFM

Aviation was the first industry to collectively commit to reducing emissions, with a clear path to achieving this goal. As part of this industry, CFM is committed to proactively contributing to the sustainable development of aviation.

Safran is one of the founders and leaders of Europe's Clean Sky Program, an industry-wide research program that is developing innovative, cutting-edge technologies aimed at reducing aircraft CO2 emissions, and noise levels. GE’s Avio Aero has also been part of Clean Sky, providing engine modules that Safran integrated into a successful open rotor demonstrator engine test in 2017.

In the past decade, GE has been part of both phases of the Continuous Lower Energy, Emissions, and Noise (CLEEN) Program, in collaboration with the U.S, Federal Aviation Administration (FAA) and National Aeronautics & Space Administration (NASA). CLEEN projects develop technologies that will reduce noise and emissions while improving fuel efficiency, enabling the industry to expedite integration of these technologies into current and future engines and aircraft.

In 2008, as a funding member, CFM was a signatory of the landmark Air Transport Action Group (ATAG) Commitment to Action on Climate Change that laid out the strategic vision for aviation’s sustainable development, including the goal of reducing net carbon emissions by 50 percent by 2050 compared to 2005 levels.

In October 2021, CFM, along with other key aviation leaders, including its parent companies, GE and Safran, has co-signed the industry declaration to adopt a long-term climate goal of net-zero carbon emissions by 2050.

The declaration, released by the Air Transport Action Group (ATAG) was signed by representatives of the world’s major aviation industry associations and largest aircraft and engine makers, each committing that “global civil aviation operations will achieve net-zero carbon emissions by 2050, supported by accelerated efficiency measures, energy transition and innovation across the aviation sector and in partnership with Governments around the world.”

The goal of carbon-neutral aviation calls for proactive, globally cohesive public policies. CFM is working closely with the entire industry to ensure that this objective can be achieved together.

Achieve a 40 percent reduction in net carbon emissions

Reducing fuel consumption is the number-one way to reduce CO2 emissions. From its very beginnings, CFM products have reduced carbon emissions by 40 percent ** to date. Today, CFM is actively investing in innovative new technologies that will bring substantial reductions for future products. More than 50 percent of our research and development investment goes toward meeting this goal.

Design and develop new technologies with a focus on continuously improving engine efficiency and reducing CO2 emissions.The next generation of CFM engines will deliver up to a 20 percent improvement in both compared to today's most efficient engines.

Support the commercial availability of Sustainable Aviation Fuel (SAF) and ensure that future engines are compatible with 100 percent SAF integration. The company began testing SAF in 2006. Since 2016, airlines worldwide have conducted more than 400,000 flights powered by sustainable fuels.

Accelerate the development of radical new propulsion technologies that will pave the way for third-generation aircraft, with:

Sustainable Aviation Fuel (SAF)

CFM believes that broader adoption of SAF is the best approach to immediately reduce carbon emissions; it has the potential to reduce aviation net carbon emissions up to 80 percent, independent of other actions.

Hybrid-Electric / Electric

Realizing the potential benefits of hybrid-electric requires advancements in the state of the art for power generation, energy storage, and propulsor technology.

Hydrogen

In February 2022, CFM and Airbus announced an agreement to collaborate on a hydrogen demonstration program that will take flight around the middle of this decade.

The program objective is to ground and flight test a direct combustion engine fueled by hydrogen, in preparation for entry-into-service of a zero-emission aircraft by 2035.

CFM will modify the combustor, fuel system, and control system of a GE PassportTM turbofan to run on hydrogen. The engine, which is assembled in the U.S., was selected because of its physical size, advanced turbo machinery, and fuel flow capability. It will be mounted along the rear fuselage of the flying testbed to allow engine emissions, including contrails, to be monitored separately from those of the engines powering the aircraft. CFM will execute an extensive ground test program ahead of the A380 flight test.

Ensuring that tomorrow’s engines support sustainable aviation growth also means considering the engine’s footprint over its entire service lifecycle. Through its parent companies:

*International Civil Aviation Organization **CO2 emitted per passenger and per travelled kilometer